Silitex … the manufacturer of technical industrial materials of

- CleanRoom & ESDfabrics

- CleanRoom garments

- High Visibility fabrics

- Flame Retardant fabrics

- Duct fabrics

have been supplying a variety of customers in 40 countries with these superior quality products over last twenty years Our specialty lies in designing and developing fabrics with exactly right style, comfort end uses.

have been supplying a variety of customers in 40 countries with these superior quality products over last twenty years Our specialty lies in designing and developing fabrics with exactly right style, comfort end uses.

Further to this, we always put more endeavor and guarantee to make our customers satisfied with quality, price, delivery and service by producing and providing the new development pursuing after customer’s needs and satisfactior.

Quality Aussurance

Silitex products are precisely checked at each stage of development, production and finishing, under strict inspection by independent third party.They have to pass numerous standards and tests before, during and after production.

Benefit to the Customers

Service

Our dedicated sales team and technical department are committed to offering a service that is second to none.

Quality Control

Silitex is accredited to ISO 9001 and ISO 14000

Continuity

Our production routes and process ensure exceptional continuity

Innovation

An on-going program of investment in new technologi

We serve such diverse markets as healthcare, microelectronics, pharmaceutical, food and beverage processing, and industries applying spray finishes.

The products are geared for comfort that meet the requirements of these various end uses, specialized precisely for customer’s needs.

Our fabrics are intended for re-use. Completely washable, they are much more economical than disposables, with typical use/wash cycles running into the hundreds. Not only will our fabrics save your money, they also make good environmental sense!

Usage and Benefit

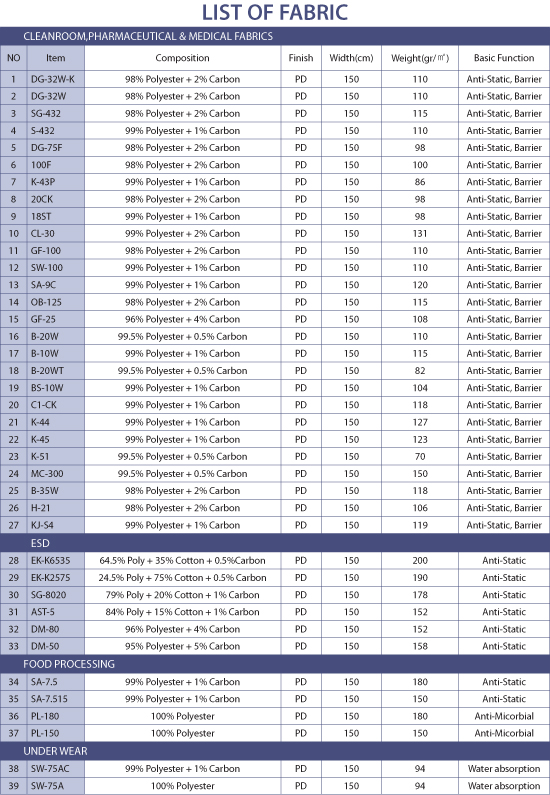

These fabrics are precisely engineered for the exacting demands of today’s cleanroom manufacturing environments.

All these fabrics are created from polyester filament yarns, which provide a non-linting barrier between potentially destructive particles and your cleanroom. They offer a high degree of surface resistivity and static decay performance to protect your products.

They ensure less particulation from your garments and through your garments to maintain a clean manufacturing environment. Also, the fabrics are environmentally friendly, reducing your garment per use and disposal costs.

Whether your static control needs also include fluid resistant concerns, worker comfort, particulation issues, or economy.

we have a static control fabric that will work precisely for you. And they are all environmentally friendly,reducing your garment per use and disposal costs.

Silitex fabrics are cost effective, highly protective, comfortable, and durable. And they are environmentally friendly, reducing your garment per use and posal costs. Below are thumbnail descriptions of our fabrics for the healthcare market. Please refer to any of these for more specific information and product data.

Using these products in your spray room ensures that you will have fewer defects on your paint surfaces, your employees will stay comfortable, and you will get the value you need from a reusable, durable, cost-effective garment. And they are environmentally friendly, reducing your garment per use and disposal costs.

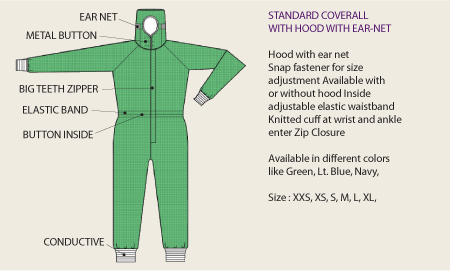

CleanRoom garments

Our cleanroom garment collection provides comfortable, easy-to-maintain High Tech garments for the micro-electronic, pharmaceutical, automotive, optical and food industries together with utstanding wear performance for cleanroom classes 1 to 100,000.

Only the highest quality fabrics and the most up-to-date developments are used and based on six key criteria:

- High durablity

- ESD performance

- Universal sterilsation protection(Steam-ETO-Gamma radiation)

- Particle barrier

- Low linting

- Comfort

Seamed, sewing threads and accessories fully meet the requirements of cleanroom users.

For every cleanroom application, Silitex offers the best solution

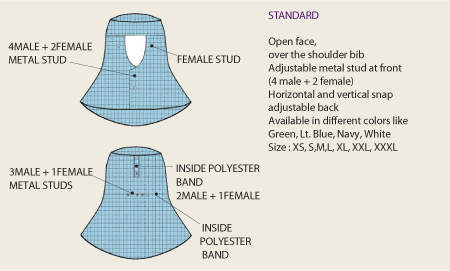

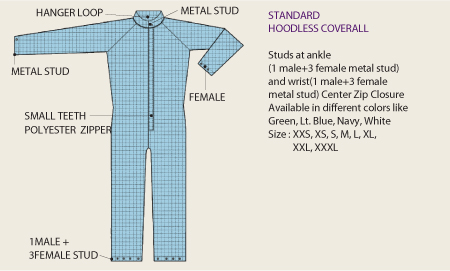

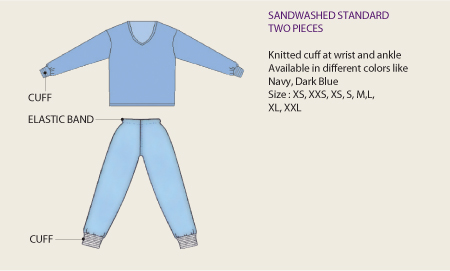

1. The standard type

The continual renewal of the epidermis produces dead cells which can be carriers of bacterial.

Our cleanroom garments hold these cells and other particles inside the garment to prevent

contamination of the cleanroom itself.

– thumb-hoop

– metal studs at the inner and outer

– leg to attach the boots

– elastic in the back

– knitted polyester cuffts at the sleeves

– knitted polyester cuffts at the leges

– elastic in the waist

– metal studs at the hood to attach a face mask

– ribbon at the back to adjust the hood

– elastic and buckle at the back to tighten the hood.

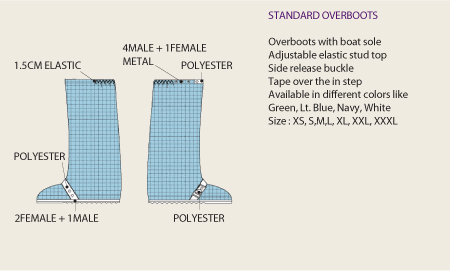

– elastic at the top

– metal studs at the sides to attach to the coverall

– with ribbon + metal studs at the top of the boot

– elastic at the top to tighten the boot around the calf

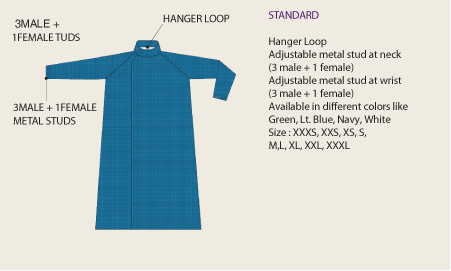

2. Garment options

Silitex offer different accessories all of which provide complete body cover without

particle leakage or blow-out.

B. Metal studs to adjust the hood

C. Metal studs to attach the face mask

D. Face mask

E. Polyester ribbon at the back to adjust the hood.

F. Polyester ribbon with the buckle at the back to adjust the hood

B. Finished with metal studs( 3 male and 1 female )

C. Finished with elastic

E. Finished with metal studs ( 3male and 1 female)

F. Finished with elastic Elastic in back

G. With fixed elastic in the back

H. With adjustable elastic in the back

I. With elastic in the waist

C. Elastic at the back and ribbons at the front

E. One piece metal buckle

F. One piece plastic buckle

G. Two piece plastic buckle Also available in gamma resistant compound

Dupont Hypalon Rubber sole, steam and ETO resistant.

Excellent durability after several sterilizations

I. Flat sole

Dupont Hypalon Rubber sole, steam and ETO resistant.

Excellent durability after several sterilizations

to ESD overstress discharge within the most critical areas of microelectronic component

manufacturer and assembly.

Silitex garments meet all recognized international standards for ESD

– 1 inside chest pocket

– 2 hip pocket

food production environment, it’s necessary.

For cleanarea ( Class 10,000~100,000) garments. Silitex Cleanarea garments

are specially designed to prevent contamination of your product and

your clean environment.

– metal studs at the sleeve to tighten the sleeve around the wrist

– elsatic in combination with flap and metal stud

– practical front pocket with flap and metal stud

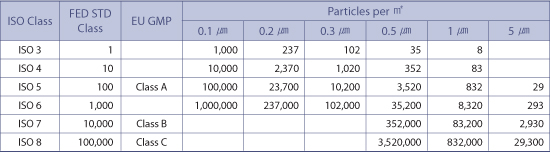

celanroom standard versus EU GMP