Lesatec was established in 1996 in order to work in Contamination Control Plants and Equipments sector.

Lesatec provides the following services:

- Clean Rooms design and construction

- HVAC systems for Clean Environments design and construction

- Devices for Contamination Control design and construction

- Isolators design and construction

- Clean Environments Validation

- Work Direction

- Turnkey plants building

- Research in fields like particles, air and temperature distribution

PRODUCTS

Lesatec developed a large set of products and accessories for Clean Rooms and for systems dedicated to contamination control.

- UNIDIRECTIONAL AIR FLOW VENTILATION UNIT

- MV12/3 | MV24/3| MV36/3 | MV48/3

- REFRIGERATORS FOR GMP CLASSIFIED ENVIRONMENT

- FOG GENERATOR

- ISOLATOR FOR HANDLING OF API

- PASS BOX WITH U.V. LAMPS

- AIR DISTRIBUTOR FOR SURGERY ROOMS

- DOWN FLOW BOOTH

- AIR SHOWERS

- INSULATION PRESSURIZER

| ISOLATOR FOR ACTIVE PHARMACEUTICAL NGREDIENTS (API) HANDLING

|

Isolator for Active Pharmaceutical ingredients is an equipment dedicated either to the handling of toxic / harmful pharmaceutical powders or to the handling of sterile products. Isolator for Active Pharmaceutical ingredients is an equipment dedicated either to the handling of toxic / harmful pharmaceutical powders or to the handling of sterile products.It is composed of two separated environments, one dedicated to the proper handling, the other to the inlet / outlet of products. Each environment is provided with a vertical – unidirectional air flow ventilation device ISO 5 class (complying ISO 14644). The accurate internal aerodynamics make this device suitable for precision weighing operations, eliminating the problem of air speed influence on pans of precision balance. Work desks, removable, are made with AISI 304 or AISI 316 pipes in order to make cleaning operations easy and effective.  Under work desks there is a collection tank for powders or for washing / sanitizing solutions. Under work desks there is a collection tank for powders or for washing / sanitizing solutions.Unit design allows to guarantee a self-safe functioning in both conditions of works (positive – negative pressures). Moreover unit external surfaces cleaning characteristics allow its use inside classified environments ISO5 . |

Main characteristics: Main characteristics:

|

Accessories:

|

MV48/3 type 5

|

Models:

|

Technical data:

|

DOWN FLOW BOOTH

Down Flow Booth is an equipment designed and realized for powders handling, weighing and sampling operations able to:

|

Main characteristics:

|

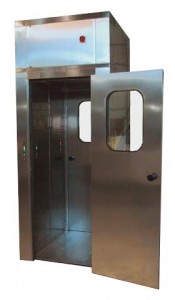

AIR SHOWER

Air shower is an equipment suitable to be used inside production environments where it is necessary to lpowders or fibres transport during the passage of operators between adjacent rooms. This scope is achieved by means of the operator “air washing”, during the transit inside the air shower, made with high speed shoots of HEPA filtered air.

Air shower is an equipment suitable to be used inside production environments where it is necessary to lpowders or fibres transport during the passage of operators between adjacent rooms. This scope is achieved by means of the operator “air washing”, during the transit inside the air shower, made with high speed shoots of HEPA filtered air.

Working principle is based on high speed air shoots capability to remove particles from clothes surfaces.

HEPA filtration of air before its diffusion inside the Air Shower make it qualified for its use inside Contamination Controlled Environments.

Main characteristics:

- Complete AISI 304 construction

- Overall standard dimensions : 1100 x 1200 x h 2750 mm

- Useful standard dimensions : 800 x 1100 x h 2100 mm

- Feed : 400V / 3F / 50Hz

- Power : 2,5 kW

- Contamination Class in “At Rest†condition : ISO 5 (ISO14644)

- Lighting system

- Flow management of staff fulfilled with interlocked doors and traffic lights

- Cycles length settable

- Emergency unlock pushbutton for doors

- DOP Test probes

- Different sizes available